PRESSING AUTOMATION RANGE

P8 DOUBLE PRESS

P7 XL DOUBLE PRESS

NET LOADER

DOLAV TIPPER

PRESSING AUTOMATION IN DETAIL

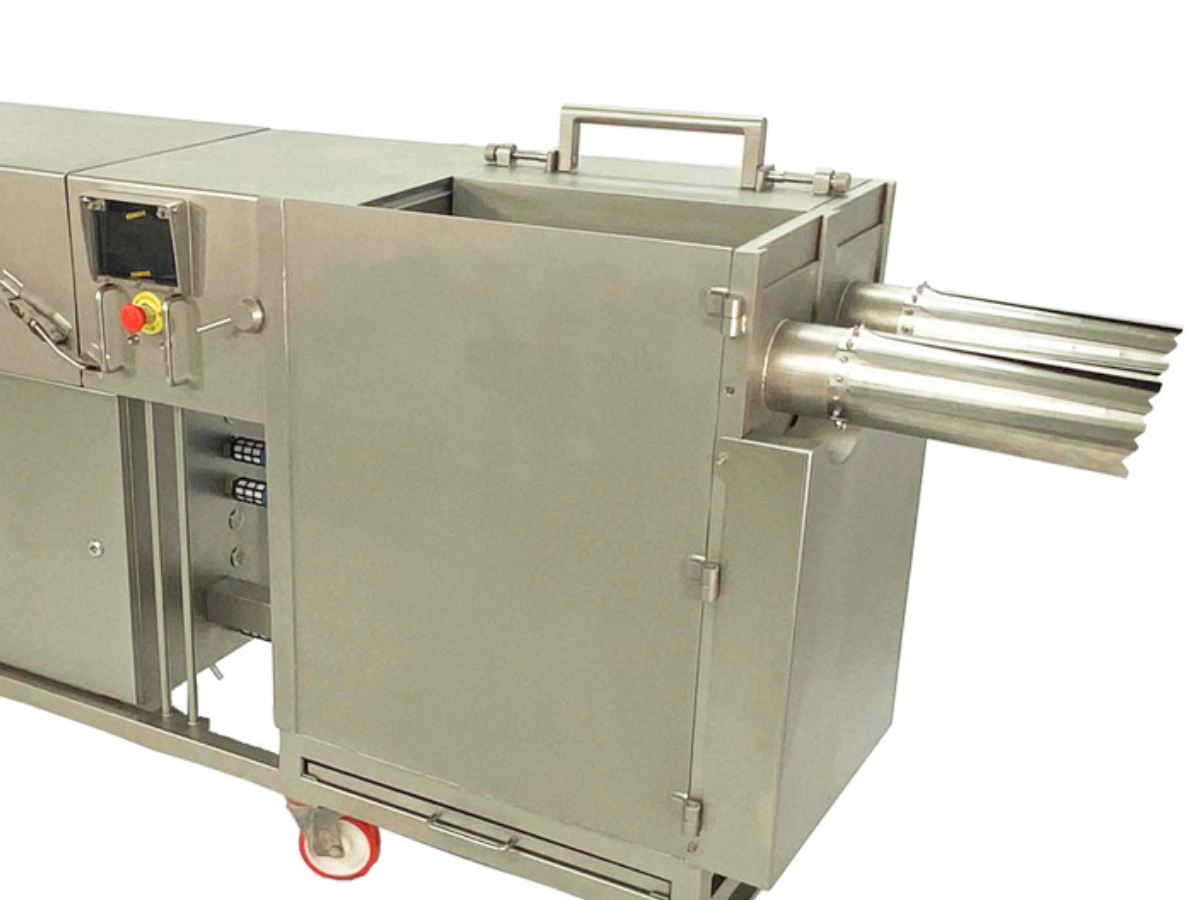

P8 DOUBLE PRESS

DS1200P8XPEfficiency, Precision, Performance

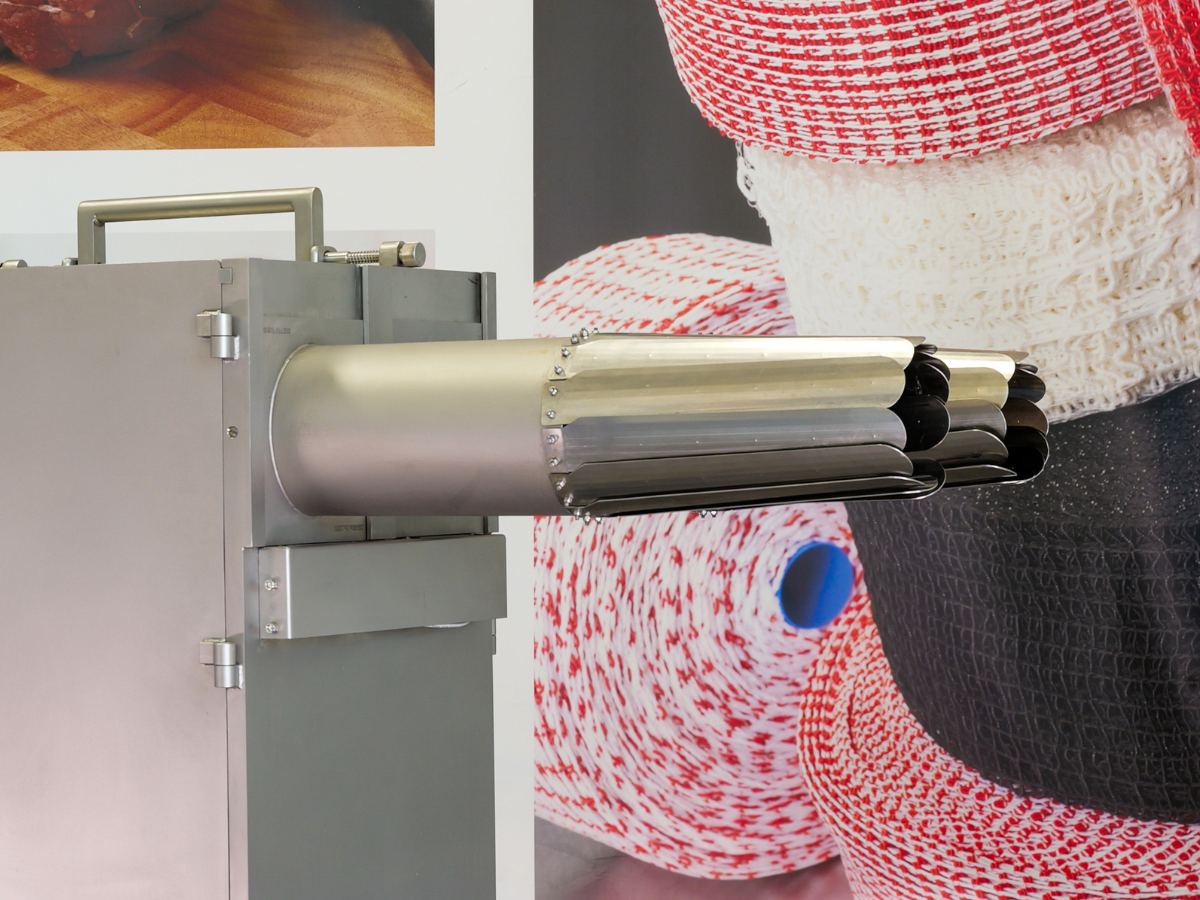

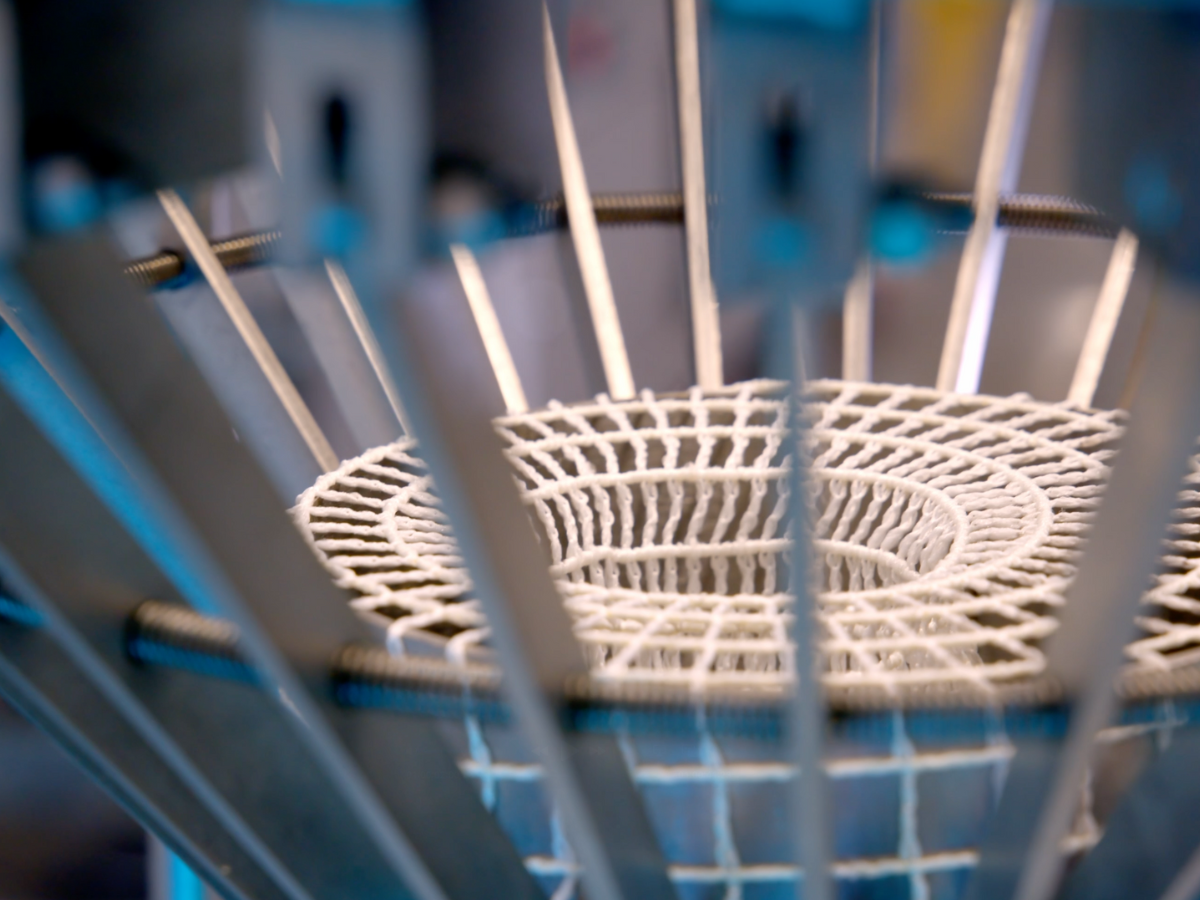

Double the Throughput. Half the Labour.- Durable Spring Steel Fingers - Engineered for long life with easy bolt-on replacement. Rounded ends prevent casing damage, while precision dimples hold casings securely during stuffing.

- Ergonomic Design - Built with operator comfort in mind. Controls are intuitively placed, loading zones are accessible, and the design minimises physical strain during long production runs.

- Hygienic Underside Design - All electrical components are safely positioned above floor level, keeping the underside clear for full washdown access. This open, elevated design reduces contamination risk and supports rigorous hygiene compliance in food production environments.

- Liquid Run-Off Management - The meat press features an integrated run-off channel, designed to capture and direct excess liquid away from the pressing area. This promotes a cleaner working environment, reduces product slippage, and supports hygiene compliance in high-volume operations.

- Intuitive HMI Interface - Simple touch-screen operation with clear prompts and diagnostics. Streamlines training, reduces user error, and enables quick setup and configuration changes.

- Enclosed Mechanical Design - Key components are protected in a sealed cupboard, shielding them from debris, moisture, and cleaning agents. This enhances reliability, extends lifespan, and maintains a clean, efficient workspace.

P7 XL DOUBLE PRESS

DS1200P7XP800DS1200P7XP800 HIGH SPEED DOUBLE MEAT PRESS

OUTPUT: UP TO 1000 UNITS PER HOUR - 2200 METERS PER DAY

About The Double Meat Press

This model has an extra-long chamber at 800mm and is for tubes that are 300mm long, and between 70mm and 200mm in diameter.These Double Meat Press machines are also known as ham presses, meat press, dual press or a euro press. Frequently used for ham making machinery, it first presses the meat, before stuffing it into casings or netting.

We design our own meat pressing machinery, which are focused on meat casing machinery and ham making machinery. The 'Scotnet Meat Press' is one of the market leaders in for double meat press machines.

NET LOADER

NL6430STEffortless Loading For All Nets and Casings

Net Loading Simplified- Netting Rolls - The Scotnet and Casings Auto Loader accommodates standard netting rolls, offering fast, reliable application for high-throughput production. Quick-load functionality keeps changeovers minimal and operations running smoothly.

- Multi-Diameter Head - The multi-diameter head adapts to a wide range of tube sizes without adjustment. Perfect for agile, multi-SKU production lines.

- Super Bobbins - Compatible with super bobbins for extended run times and reduced handling. This format minimises downtime and maximises output between reloads.

- Quick Change Head - The quick-change head system enables engineers to change the head in minutes. Reducing maintenance and downtime to a minimum.

DOLAV TIPPER

DSHOISTEffortlessely Tip Dolav Bins - No Strain or Stress

About the SCOTNET Dolav Bin Tipper

The Scotnet Dolav Bin Tipper has been specifically developed to tip the 1000mm x 1200mm Dolav style plastic bins from floor level onto one of our hoppers for feeding directly into our DS1200 Double Stuffers and DS1200PXP Double Presses.

Our tipper is fully guarded, enabling the stuffer operator to control the tip, without movin from his position.

- Pneumatic Tipping - eliminating any potential contamination from a cylinder leak.

- Reduce Fatigue - Eliminates bending and lifting, the product is effortlessely delivered exactly to the operator ready for loading into the chamber of the stuffer or press.

- Light Curtain Guarding -No gates or moving guards, simply load the bin into the machine, and the light curtain provides total security, enabling the tipping controls to be postioned at the stuffing operator.

- Electronic Controls - Simple to control, with Up/Down buttons, and hold at any point during the lift.

- Easy To Clean - Fully stainless steel design with quick-clean access built in, no tools or engineers required to prepare the machine for cleaning.

PRESSING AUTOMATION STORIES

Autoloader Advert Overview

A detailed look at the Autoloader

A detailed look round the multi loader.

The P8XP meat press advert.

A detailed look round the P8XP meat press.

Eliminate strain, the Dolav tipper with our double stuffer.